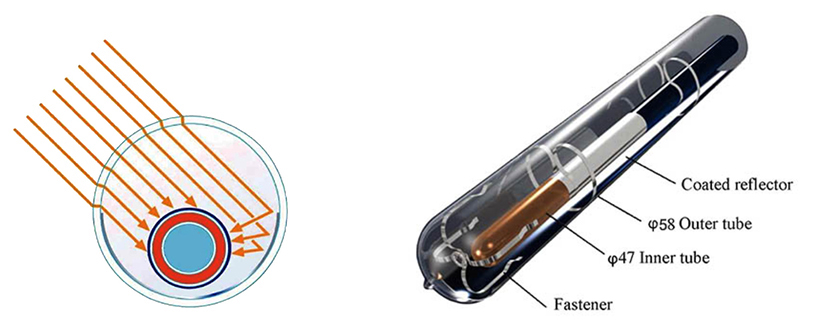

The Evacuated (Vacuum) Tube:

Each evacuated tube is composed of two concentric glass tubes; the inner one is coated with highly selective layer and it converts solar radiation into thermal energy. As for the outer one, it is used as a cover to keep the vacuum. Both tubes are fused together and the gap between them is evacuated to achieve excellent thermal vacuum insulation.

Why Vacuum Tubes?

Vacuum (evacuated) tubes works like a thermos flask, which uses vacuum to provide thermal insulation. Once the evacuated tube absorbs the radiation -of the sun and converts it to heat - the vacuum helps maintain temperature. The vacuum insulation makes evacuated tube collectors outpace the traditional flat plate collectors in performance.

| Evacuated tubes | |

| Glass material | Borosilicate Glass 3.3 |

| Outer tube dimeter and thickness (mm) | ᶲ58 1.8 |

| Inner tube dimeter and thickness (mm) | ᶲ47 1.6 |

| Coating | ALNO/ALNOSS/Cu |

| Degree of vacuum (Pa) | ≤5.2x10-4 |

| Hail proof (mm) | 25 |

| Absorption coefficient | ≥0.94 |

| Emittance | ≤0.06 |

| Average heat loss coefficient (m2.C/KW) | ≤0.5 |

| Maximum temperature (ﹾC) | 300 |

| Service life (yrs) | 15 |

| Length (m) | 1.8 |

| Hot Water Tank | |

| Structure | Dual layered water cylinders |

| Inner tank material | stainless steel 304 Food grade |

| Inner tank thickness | 0.4mm |

| Outer tank material | PVDF Coated galvanized steel |

| Outer tank thickness | 0.4mm |

| Tank insulation | 50mm polyurethane |

| Silicon rubber | UV stabilized high temperature |

| Cold Water Inlet | ½” |

| Hot Water Outlet | ½” |

| Packing | Recycled Card Board (Export) |

| Manufacturer Warranty | 5 years |

|